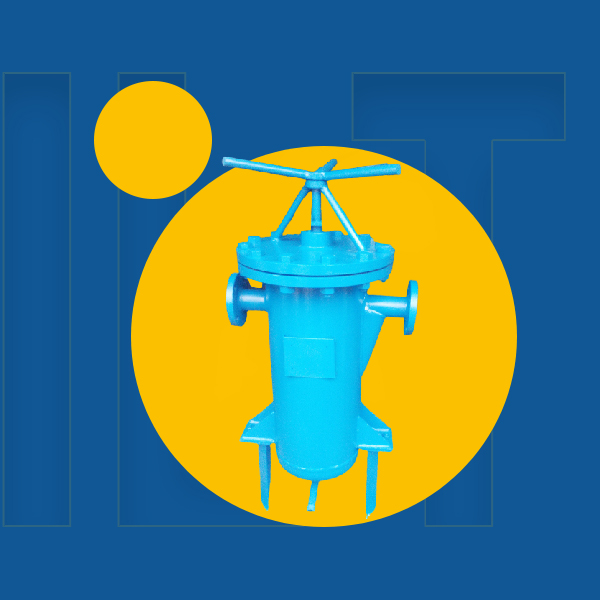

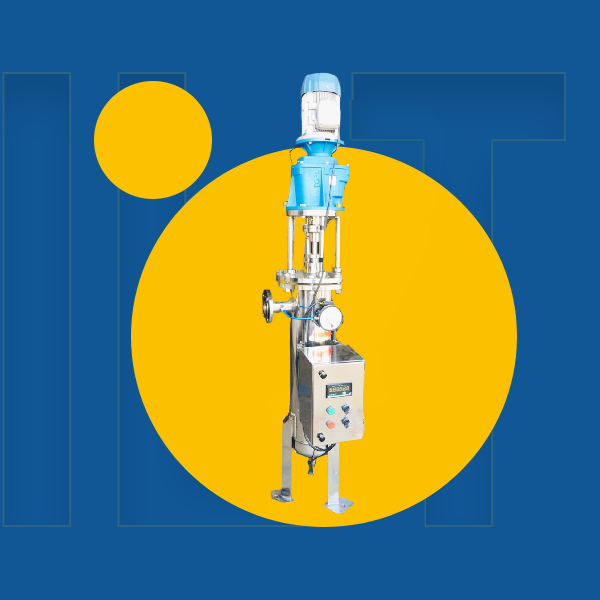

Strainers

Home » Self Cleaning Filter

Self Cleaning Filter

Technical Parameters

- Line Size: 1” NB to 20” NB

- End Connections: 150# & 300# Flanged, Table E & Table F Flanges, DIN Standard Flanges

- Material of Construction : CS, MS, SS304, SS304L, SS316, SS316L, SS317L

- Operating Pressure: 0 to 10 Bar

- Operating Temperature: 15 Deg. C to 100 Deg. C

- Flow Rate : Up to 100 M3/Hr.& More

- Filtration Rating : 100 Micron to 6000 Micron & More

- Top cover with nut & bolts type or quick opening type

Advantages:

- Auto Cleaning Type Design

- Low Pressure drop

- Large area

- Easy to operate and maintenance

- Positive Sealing to prevent bypass

- Customized design

- High dirt load holding capacity

Applications:

- Refineries and Petrochemicals

- Power Plants

- Oil & Gas

- Water filtration and Cooling Towers

- Chemical Industries

- Automobile Industries

- Steel Industries, Metals & Minerals

- Textile Industries

- Dairy and Food Industries

- Dyes, Inks and paints Industries

- Cement Industries

- Fertilizers Industries

- Pharmaceuticals

- Coolant Oils and Cutting Fluids

Leading Self Cleaning Filter Manufacturers in India

UWS FILTERS are manufacturing Self-cleaning filters for various applications. They are commonly used for continuous filtering without the need to change filter consumables or need intervention of an operator. Our Self-Cleaning Filters ensure uninterrupted flow, trouble-free operation, and easy maintenance. The method of cleaning the filter is by using a Scrapper Mechanism that cleans up the clogged impurities from the filtering screen, and gets triggered either by a set timer and/or a differential pressure across the filter. During the cleaning cycle, a solenoid drain valve opens up and the dirt that is scraped is drained off. This operation happens till a pre-set pressure drop is reached, where-in, the drain valve is shut and the filtration process is continuously on. Self-Cleaning filters are used for preliminary filtering. Cleaning the element is as simple as turning a knob or outer shaft handle manually or by using a geared motor. Contaminants are removed from the element surface with a Brush or Scraper Blade and gathered at the bottom, where they may be periodically drained.

The UWS FILTERS Self-cleaning filters are utilized in applications that need continuous filtering without the replacement of filter consumables or need to open the filter. Filter housing, wedge wire or wire screen mesh media filter element, scrapper system, differential pressure measurement instruments, auto control discharge system, a control panel and scrapper drive system are the components of self-cleaning filters. Self-cleaning filter is used for unattended continuous filtration. In various industries, solid liquid separation especially larger particles are increasingly being done using these types of filters.

Our Self-Cleaning Filtration System is simple and satisfies the requirements of our clients. The self-cleaning filters are mounted in the pump discharge side as it needs some pressure for effective filtration as well as self-cleaning operation.

Self-Cleaning Filters/Strainers are specially designed for liquid filtration with continuous operation. Self-Cleaning filters has been designed to increase the efficiency of production and low maintenance cost. Due to its self-cleaning design, no stoppages needed to change strainer elements or slowing of throughput due to blockages.

In a self-cleaning filter/strainer, a rigid cylinder screen strains particles from a water /chemicals source, trapping debris on the inside. This layer of build-up causes differential pressure across the inlet and outlet. A controller monitors the filter and opens a flush valve when it senses adequate differential pressure. Our Self-Cleaning Filter available in MS/CS and Stainless Steel MOC