SS FILTERS

Leading SS Basket Strainer / Filters Manufacturers in India

UWS Filters are a large manufacturer of SS Basket Strainer/Filter in the country. Sold under the brand name of “Guru”, these are generally used to separating coarse particles. Strainer/Filter elements are easy to remove and clean. We offer basket filter with flow direction in to out or out to in as per dirt load and application. Basket Filter design available with single strainer element, double cylinder type strainer element, multi strainer elements and pleated type strainer elements. Our Bucket Strainer in MS/CS MOC is available with Painted, hot dip galvanized or powder coated. Basket Filter in SS MOC is available with mirror polished both side or glass bead blasting.

1.Simplex Bucket/ Basket Strainer / Filter

2.Multi Bucket/Basket Strainer / Filter

3.Duplex Bucket/Basket Strainer /Filter

4 .Jacketed Type Bucket Strainer/Filter

5.Jacketed Type Duplex Bucket Strainer/Filter

6.POT Type Strainer

7.Y Type Strainer

8.Conical Strainer

9.T Type Strainer

10.Self-Cleaning Filter

SS Bucket Strainer

Basket strainers are installed to protect equipment from damage caused by unwanted debris that may be in the pipeline. The unwanted debris could be dirt or other foreign particles that make their way into the process fluid. Typically, basket strainers are installed in horizontal pipelines and in situations where high flow capacity is required.

These strainers are installed upstream of equipment like pumps, control valves, and traps, keeping potentially corrosive or damaging debris from making its way down the line. They can be installed alone or in a series to increase filtration. They may come with a single chamber (simplex strainers) or multiple chambers (multiplex strainers). To read more about the differences between simplex and duplex strainers, check out this post.

SS Multi Bag Filter

Multi-Bag strainers are used in processes in which very high flow rates or very low-pressure differentials are required, and where high dirt contaminant levels exist.

The main advantage and great benefit of multi-basket strainers is the increased filtration area they provide. This minimises the fluid face velocity over the filtration media, which induces low-pressure differentials. The increased surface also provides increased dirt holding capacity. The other great benefit is that the baskets can be kept to a reasonable size and weight for handling.

SS Duplex Basket Filter

UWS manufactures many types of Duplex Stariners, which is used for continuous operation without stoppage of filtration process. Duplex filter is also known as one working and one stand by filter.

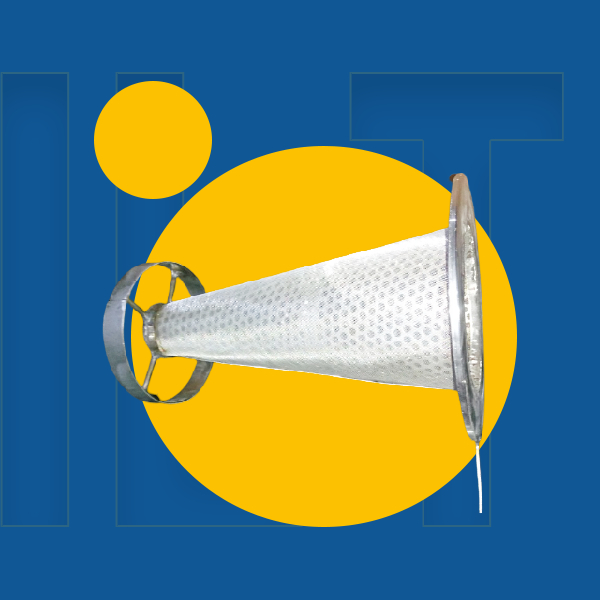

Conical Strainer/Filter

UWS FILTERS offers Conical Strainers for different pipe sizes. These are also known as temporary Strainers. Applications include pipeline flushing during commissioning, protection of gas and liquid flow meters They are used before startup of a plant as pre filter. Conical strainers use perforated wire mesh or wedge wire to trap suspended particles or impurities from the fluid/stream. Conical Strainers are very cost effective straining solutions in many applications.

Conical strainers mechanically remove unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element and are commo…

Y Type Strainer/Filter

When deciding which type of strainer to use, it is important to understand the specific purposes and differences that make a strainer unique. Wye strainers are no exception. While this strainer option is more flexible when compared with basket strainers, the y strainers have a very limited installation. The y type strainer purpose is a specific one and that is exactly what makes them ideal for the applications where they can be used. This means that understanding the y strainer purpose and the applications that benefit from it are the best ways to get the results that you are looking for out of this strainer!

Self Cleaning Filter

UWS FILTERS are manufacturing Self-cleaning filters for various applications. They are commonly used for continuous filtering without the need to change filter consumables or need intervention of an operator. Our Self-Cleaning Filters ensure uninterrupted flow, trouble-free operation, and easy maintenance. The method of cleaning the filter is by using a Scrapper Mechanism that cleans up the clogged impurities from the filtering screen, and gets triggered either by a set timer and/or a differential pressure across the filter. During the cleaning cycle, a solenoid drain valve opens up and the dirt that is scraped is drained off. This operation happens till a p…